POLYURETHANE for External & Internal Pipe Coating

BITUMAX through it’s marketing arm BITUMAX TRADING SDN BHD was appointed as a representative of TIB CHEMICALS AG / GERMANY to market it’s popular brand of PROTEGOL® coating systems in 2019. PROTEGOL® is a registered trademark of TIB CHEMICALS AG/ GERMANY. The territory covers countries such as Malaysia, Philippines, Indonesia, Singapore and Vietnam.

PROTEGOL® polyurethane coating system provides long-life protection and exceptional mechanical and chemical properties against corrosion attack and soil stress of buried and submerged pipes, bends, valves and fittings. An expertise of decades and a constant strive for innovation makes it one of the leaders of coatings for worldwide oil, gas and water projects.

It’s variety of polyurethane grades available for a range of oil, gas and water transmission lines, industrial installations such as tanks, valves, and fittings.

Technical advantages:

- High protection against corrosion, mechanical and chemical attack

- One-coat solution direct to steel or cast iron

- Fast curing

- Excellent adhesion to steel and FBE

- Good adhesion to PE/PP

- Compatibility to cathodic protection even at elevated temperatures

- Good stability and mechanical strength during pipe handling and laying

Packing:

- In 200 liters steel drums for plural system spray equipment

- In 2k cartridge system for air-assisted spray with pneumatic discharge device

- In 2K cartridge system for repairs with mechanical discharge device

- In 2kg tin double pack manual application by brush for repairs

PROTEGOL® Coatings - Solution to Success

BITUMEN IMPREGNATED OUTERWRAP for Pipe Coating

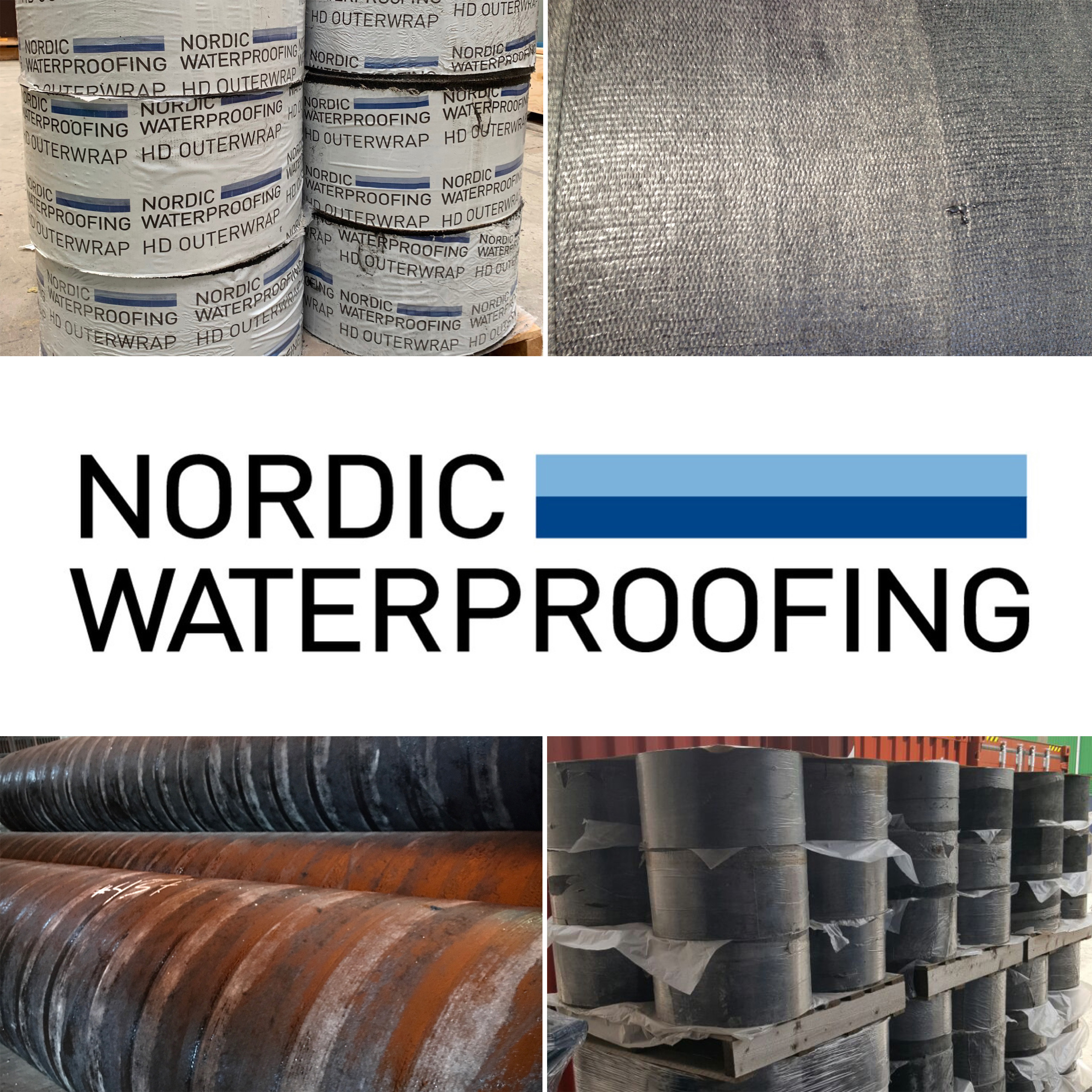

BITUMAX was appointed as a distributor from a well-known company Nordic Waterproofing A/S from Denmark for the distribution of Outerwrap to Malaysia, Singapore, Indonesia, Philippines and Thailand.

BITUMAX distributes two types of high-quality outerwrap for reinforcing the mechanical properties of Enamel for pipe coating.

- NWP GT 650 Outerwrap is a bitumen-impregnated glass mat produced with continuous glass fibre threads lengthwise combined with a glass mat. The outerwrap is impregnated with bitumen to ensure optimum protection of the fibres. The product is manufactured to an exact degree of porosity, which promotes effective adhesion between outerwrap and enamel. GT 650 Outerwrap is very flexible and mainly used on offshore pipelines on shallow water, where only minor shear value between the coating and the concrete is required.

-

NWP Heavy Duty Outerwrap is a bitumen-impregnated woven material produced by the regular weaving of continuous glass fibre threads lengthwise and double stapled glass fibres crosswise. Outerwraps are impregnated with bitumen to ensure optimum protection of the fibres and to facilitate “ a controllable bleed-through” of the enamel. The product is manufactured to an exact degree of porosity, which promotes effective adhesion between outerwrap and enamel.

Heavy Duty Outerwrap is very flexible and mainly used on Deep water offshore pipelines to obviate sheer stress arising from the concrete weight coating.

Both types of Outerwrap above are manufactured by Nordic Waterproofing A/S, Denmark and fully compatible with BITUMAX Primer Type 1 and Type B and BITUMAX Asphalt Enamel. Both types of Outerwrap meets the requirements of EN10300:2005.

Packing:

In rolls of 12 rolls/pallet and packed in shrink foil. Available size :

- 9” x 1200’ of 82 meter square per roll

- 12” x 1200’ of 112 meter square per roll

STEEL GRIT AND STEEL SHOT for Pipe Blasting

Abrasive blasting is the first important step in surface coating preparation, as it cleans a substrate and creates a surface that will hold a protective coating. Abrasive blasting is more commonly known as sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove contaminants.

BITUMAX supply high quality and durable abrasive materials for good surface preparation of steel surfaces. It not only cleans the surfaces but create a profile to receive the protective coatings. Thus, the protective coating can be applied effectively with very good adhesion to steel surfaces.

BITUMAX supply two types of abrasives as below:

Steel Grit available grade : G10, G12, G14, G16, G18, G25, G40, G50, G80, G120

Steel Shot available grade : S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Steel Shot available grade : S780, S660, S550, S460, S390, S330, S280, S230, S170, S110, S70

Packing:

- In 25kg paper bags of 60bags per carton box on IPPC pallet