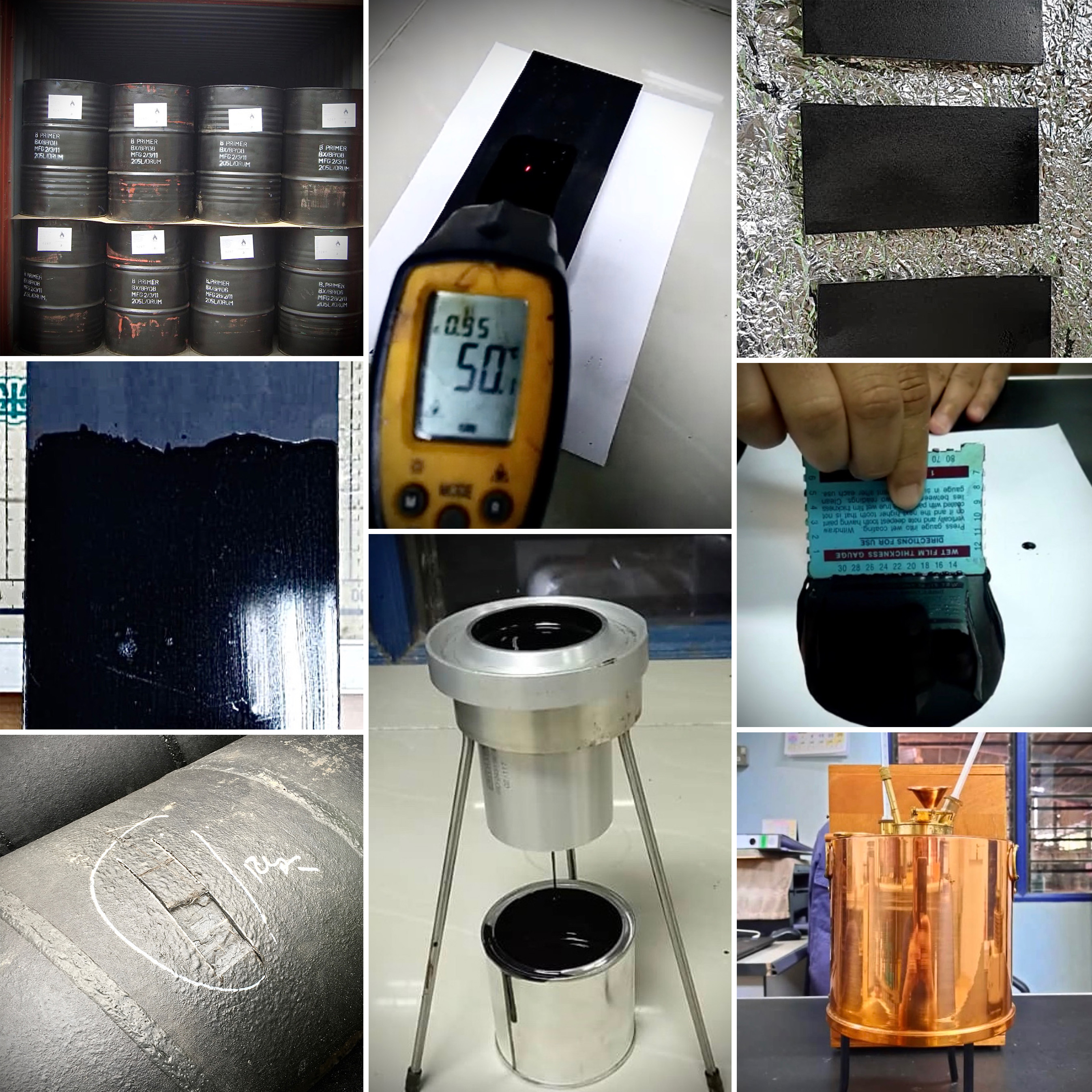

Bitumax Bitumen / Asphalt Enamel

Bitumax Asphalt Enamel is produced by oxidizing high quality and carefully selected bitumen through an oxidizing process in a blowing column. Oxidized bitumen and inert non-fibrous fillers are then uniformly mixed to produce this product for the coating of oil & gas and water pipes. It is a very versatile material that adheres well to metal surfaces. It is impact-resistant, does not impart any odor to water and is also highly electrical-resistant. It will soften gradually when heated and will change back to solid form on cooling. Bitumax Asphalt Enamel is mainly used as anti-corrosion materials for protection of iron and steel pipes for the oil & gas and water industry.

Bitumax Asphalt Enamel meets the requirements of:

- BS EN10300:2005 Category 1 Grade A,B & C

- BS4147:1980 Type II Grade A,B & C

Technical advantages of Bitumax Asphalt Enamel:

- Excellent and permanent adhesive to metal

- Low water absorption

- Impact resistant

- Flexibility

- Resistant to soil stress

- Resistant to cold stress

- High electrical resistibility

- Chemically stable

Packing:

- In cylindrical molded keg form of approximately 170kg per keg and palletized into 6-9 kegs/pallet

- In 25kg or 40kg kraft paper bags and palletized into 40-50 bags/pallet

Bitumax Primer Type B And Type 1

Bitumax Primer Type 1 & Type B is based on chlorinated rubber dissolved in organic solvent. It is very quick drying and can be applied by roller, rugs, brush, air-less and conventional spray. Its quick drying properties permit pipe sections to be hot coat and wrapped within minutes. It may be used for both internal and external priming of pipes.

Technical advantages and uses of Bitumax Primer Type 1 & B:

Its free flowing properties permit coverage of 8-16m² per liter (400-800 ft² per imperial gallon) on new pipe surfaces.

- Great increased in bond factor compared to conventional coal tar and bitumen primer

- Compatible with both Asphalt and Coal Tar enamel coatings

- Remains active for months after application

- It can be used for internal & external of pipes

- It imparts no odor or taste

Its free flowing properties permit coverage of 8-16m² per liter (400-800 ft² per imperial gallon) on new pipe surfaces.

Bitumax Primer Type 1 and Type B meets the requirements of:

- EN10300:2005 Table 1 (Bitumen)

- BS4147 Type B (Bitumen)

- BS4164 Type B (Coal Tar)

- AWWA C203 Type B (Coal Tar)

- International Standard ISO5256

Packing:

- In steel drums filled up to 200 liters per drum

- In metal pails filled up to 20 liters per pail

Bitumax Bituminous Primer Bs4147:1980 Type A Grade B

Bitumax Primer BS4147:1980 TYPE A GRADE B (TYPE A) is based on specially oxidized bitumen grade dissolved in organic solvent. It can be applied by roller, rugs, brush, air-less and conventional spray.

It’s a low viscosity bituminous solution and an essential primer for steel and iron pipes before application of bitumen based coating enamel. It is highly penetrative and has good adhesion to most surfaces. It may be used for external priming of pipes. Bitumax Primer Type A meets the requirements of BS4147:1980 Type A Grade B.

Packing:

- In steel drums filled up to 205 liters per drum

- In metal pails filled up to 20 liters per pail

BITUMAX BITUMINOUS SOLUTION BS-1C for Ductile Iron Pipe coating

Bitumax Bituminous Solution BS-1C (Primer BS-1C) is a low viscosity blend of specially formulated oxidized grade bitumen in solvent without fillers. It is cold apply, highly penetrative thin bituminous paint and forms a high quality durable bitumen film. It’s a premium quality low odor solvent base bitumen primer and used as a protective external coating of ductile iron pipes.

Packing:

- In steel drums filled up to 209 liters/drum

- In round metal pails filled up to 20 liters/pail

- In rectangular tin containers filled up to 5-20 liters/tin

BITUMAX BITUMINOUS MASTIC TYPE A & B for Anode Gap Fillings & Field Joints of Pipes

Bitumen mastic is a blend of suitable graded aggregates with a bituminous binder. The important properties of the bitumen mastic are determined by the bituminous binder, which is the specially oxidized grade of bitumen, which is an un-reactive high flash point hydrocarbon derived from the distillation of petroleum crude oil. It is mainly used in pipeline industry as field joint application and filling of anodes gap on pipelines. The difference between various types of mastic is the amount of and grade of the Oxidized Bitumen being used.

Bitumax produces 2 types of standard grade bitumen mastic:

- Type A (without filler)

- Type B (with filler)

Packing:

- In 25kg or 40kg paper bags